Fabric Objective Measurement Techniques

Abstract

The objective of the research reported here is to develop a virtual fabric handling experience using a haptic display. Development of the capability for haptic simulation of fabric hand requires a feedback system to translate fabric property data into a virtual haptic display. First of all we are establishing the representative force profile for a fabric and develop a touch feedback system capable of accurately simulating the amplitude and frequencies required. The Kawabata KES-F system provides the basis for these force profiles. The reactive forces on the fingers and hand associated with feeling a fabric are duplicated using highly sensitive touch response transducers. The user of this device will be able to evaluate fabrics in a virtual sense. Ultimately such a device could be coupled with a web-based system to allow consumers to make a hand evaluation of fabric before making purchase decisions on garments. In this paper I would mainly focus on the Haptic Simulation of Fabric Hand, which is an upcoming application of the fabric objective management technology.

Introduction

Fabric Hand

Fabric hand refers to the total sensations experienced when a fabric is touched or manipulated in the fingers. Term "fabric handle" or simply "handle" or "hand" is also used. It is a complex parameter and is related to the fabric properties such as flexibility, compressibility, elasticity, resilience, density, surface contour (roughness, smoothness), surface friction and thermal character.

Factors Affecting On Fabric Hand

In textiles raw material, yarn structure, planar structure and finishing treatments affect the fabric hand. Yarn is composed of fibres and they are either staple or filament length. All natural fibres except silk are staple length fibres. Silk and manmade fibres may be staple or filament length. Fiber size is usually specified in terms of diameter or linear density. The finer the fibres the smoother and more flexible is the yarn and the fabric will drape beautifully. Also the fiber length affects to the smoothness of the yarn. The longer the fiber and the smaller the fiber length distribution, the smoother is the spun yarn. The cross-sectional shape of the fiber affects to the smoothness of the yarn, too.

Filament yarns composed of one filament are called monofilament yarns and those with many filaments are called multifilament yarns. For apparel fabrics multifilament yarns are usually used. Comparing multifilament yarns of the same size and fiber composition, yarns containing more filaments (finer) are much less stiff than multifilament yarns containing less filaments (coarser). Flat multifilament yarns are yarns in which the filaments are straight and well aligned with the yarn axis. They tend to be the smoothest of all types of yarns. Textured yarn is a generic term given to the filament yarns with greater apparent volume, which is achieved through physical, chemical or heat treatments or a combination of these. The feel of textured-yarn fabrics against the skin is considerably different than that of flat-yarn fabric. Textured yarns give a fabric more pleasant hand, fabric becomes warmer and softer and it has less synthetic feeling) [1].

Properties of yarns and of fabric made from them are influenced by the degree of twist in the yarn. As the twist is inserted, the fibres or filaments come closer each other. High twist gives greater bending stiffness. In plied yarns, i.e. two or more single yarns twisted together, the stiffness is increased compared to single yarns.

In woven fabrics the weave and the yarn densities affect to the fabric hand. Variations in warp and weft densities and in warp and weft numbers have a significant effect to the hand. Feeling depends also on the weaves in woven structures (cf. terry fabric, velvet, and velveteen, corduroy, satin, twill, rib weave, plain).

Knitted fabrics are made of stitches and they are divided into two groups; weft knitted and warps knitted fabrics. In weft knitted fabrics stitches made by each thread are formed substantially across the width of the fabric. In warp knitted fabrics the stitches made from each warp thread are formed substantially along the length of the fabric. The simplest weft knitted fabric is plain jersey, where all stitches are pulled to the same side of the fabric. It is possible to produce many variations based on this plain jersey, e.g. Jacquard fabric that shows a multicolored design motif on the effect side and floats (connects two loops of the same course that are not in adjacent wales) on the reverse side.

Plain jersey stretches equally in the two axial directions, but floats reduce stretch significantly in cross direction. It is also possible to produce e.g. terry fabrics or pile fabrics based on plain jersey. Another usual group of weft knits are rib knits, which have greater stretch crosswise than lengthwise. If you compare warp knitted fabrics to the weft knits, you can notice that warp knits are not so elastic than weft knits (if elastic yarns are not used). You can also influence to the surface structure for example by using tuck loops or by transferring stitches. By knitting it is not possible to produce so tight fabrics than by weaving. The density of knitted fabric depends on the gauge (needle density) of the knitting machine.

Nonwoven fabrics differ from knitted or woven fabrics, because they are not based on yarns. They are based on webs of individual fibres, which can be bonded to each other by several means. The texture ranges from soft to harsh. Fiber composition influences performance far more for nonwoven fabrics than for fabrics containing yarns. High strength combined with softness is one of the most difficult property combinations to achieve in nonwoven fabrics because the geometrical factors that permit high strength also lead to increased stiffness.

Finishing is an extremely complex subject because of the large number of changes that occur in fabric properties during a finishing sequence. The effects of many finishing operations are interactive; the total effect of a sequence of operations is not the sum of the individual operations. There is an interaction between fabric construction and finishing such that the effect of finishing on fabric properties will depend on both the finishing route and the construction of the loom-state fabric. By using various finishing treatments different kind of end products can be produced from the same unfinished woven or knitted fabric. Heat treatments may cause fibres to crimp increasing the bulk of the fabric. Light brushing gives peach-skin type fabric woven from microfibers. By calendaring you get flatter surface and also many chemical treatments (softening compounds, resins) can affect to the fabric hand. The diversity of fabric types and finishes that is available for any end-use continues to increase, making the selection of the most appropriate fabric an increasingly difficult task.

Subjective and Objective Measurement of Fabric Hand

Fabric hand attributes can be obtained through subjective assessment or objective measurements. Subjective assessment is the traditional method of describing fabric handle based on the experience and variable sensitivity of human beings. Textiles are touched, squeezed, rubbed or otherwise handled to obtain information about physical parameters. The subjective assessment can also be described as a psychological reaction from the sense of touch, as the tactile sensitivity of people varies according to age, skin hydration, cultural aspects or gender of the test person. In the clothing industry professional trained handle experts sort out the fabric qualities.

Objective assessment has a different primary goal: it is to predict fabric hand by testing relationships between sensory reactions and instrumental data. In 1930 Peirce described first a way of measuring some fabric mechanical properties related to fabric drape and fabric hand. Lindberg and Dahlberg later established the relationship of properties and garment appearance in 1961. The KES-F system (Kawabata hand evaluation system for fabrics) was developed in Japan by the Hand Evaluation and Standardization Committee (HESC, established in 1972) organized by Professor Kawabata. In this fabric objective measurement method scientific principles are applied to the instrumental measurement and interpretation of fabric low stress mechanical and surface properties such as fabric extension, shear, bending, compression, surface friction and roughness. The fabric handle is calculated from measurements of these properties. Since then, it has been widely used in the studies of fabric mechanical properties. In parallel Postle conducted research on fabric handle and methods of linking the fabric objective measurements with the subjective assessments.

SiroFAST (Fabric Assurance by Simple Testing) is the most recently developed integrated set of instruments and test methods available for fabric objective measurement. SiroFAST measures the mechanical and dimensional properties of fabric that can be used to predict performance in garment manufacture and the appearance of the garments in wear. SiroFAST was developed in Australia by the CSIRO Division of Wool Technology to meet industry's need for a simple, reliable method of predicting fabric performance. Despite SiroFAST simple appearance, it is based on considerable research into the relationships between measured fabric properties and fabric performance.

Fabric objective measurement, in particular SiroFAST, is currently being used by fabric and garment manufacturers in many pans of the world in a wide variety of applications. The difference between tactile properties and objective measurement of mechanical properties was connected quantitatively by a number of statistical techniques. These studies conducted in Japan and Australia had led to an important step towards handle standardization.

Today's most exact devices, the Kawabata Evaluation System (KES) and the Fabric assurance by simple Testing (FAST) method, both systems measure similar parameters using different instrumental methods. Additional techniques consist of the ring or slot tester, which tests are less accurate but faster and cheaper to handle. However, although objective assessments are precise from a mechanical point of view, these methods have not been commonly used in the textile and clothing industry. Even today many companies still use subjective evaluation to assess fabric properties. The main reason for this situation is the repetitious and lengthy process of measurement and the lack of knowledge for a good interpretation of the test results.

Now let us have a look at the various fabric properties.

The Properties of Fabrics

The properties of fabrics can be loosely described as either functional or aesthetic.

- Functional properties relate to the failure (normally mechanical) of the fibers or yams that make up the fabric during use.

- Aesthetic properties are the most highly subjective and complex features of fabrics. They include appearance and handle, and involve visual or tactile aspects of the fabric, rather than simply the nature of fabric, yarns or fibers.

Fabric Properties Related To Handle

The fabric properties related to handle, performance in garment manufacture, and garment appearance after manufacture and in use are, Physical properties (thickness and weight); dimensional stability (relaxation shrinkage and hygral expansion); mechanical properties (extensibility, bending properties, shear properties and in-lane compression); surface properties (compression, friction and surface irregularity); optical properties (luster); performance properties (pilling, wrinkling and surface abrasion).Objective Measurement and Fabric AestheticsThe idea of using the objective measurement of properties to predict fabric performance is not new. Measurements have been used to predict some aspects of fabric performance for many years. However, fabric objective measurement in the context of this report involves quite different objective measurements. The tests described in this report are designed to predict the success or failure of a fabric to 'make up well', to feel 'good', or for garments to look 'good' after manufacture and 'in wear'. This requires very subtle measurements that are much more accurate than those required to cause fabric to 'fart in the normally accepted sense. The difference between the testing referred to in this report and that previously required to predict functional performance, is that testing to assess aesthetic properties involves measurement at low deformations.Recently, techniques have been developed to measure the mechanical properties of fabrics and use these measurements to quantify handle and quantitatively predict performance in both garment manufacture and the appearance of garments. However, mechanical properties are not the only properties that determine fabric aesthetics. Thermal properties, such as insulation and the warm-cool touch sensation, also play an important pan to determining fabric handle. The so-called dimensional stability of the fabric (perhaps more correctly called dimensional instability t12)) is also critical, not only in the manufacturing process but also to the subsequent appearance of the garment in wear. The need for tests to predict or assess subjective aspects of fabric aesthetics has increased in recent years for three main reasons:- The trend towards light-weight clothing has resulted m the increased use of fabrics that are difficult to make-up and require new handling skills,

- The trend towards shorter seasons and the use of rapid systems (such as just-in-time manufacturing), have meant that the delivery of fabrics that are difficult to make-up will disrupt production schedules. For this reason it is even more important that garment makers are able to predict fabric performance.

- The increased use of automation m garment manufacture removes the opportunity for skilled operators to correct for difficult or variable fabrics.

Instrumentation for Objective MeasurementMeasurement of all the properties that determine important aesthetic characteristics of fabrics is not feasible for industrial users. However, fabric or garment makers require a system that measures only the necessary properties to achieve satisfactory quality control. Research workers to measure individual fabric properties, such as thickness and extensibility, have used simple instruments for many years. Until recently, the use of these separate instruments to predict fabric performance was not sufficiently coordinated to be widely used except by a small sector of the fabric and garment manufacturing industries.Two developments have rinsed the status of fabric objective measurement from a research instrument to a tool suitable for use in industry:- The availability of a set of instruments those are relatively inexpensive and simple to use.

- The coordination of background information needed to interpret the large amount of data produced by the instruments and uses it to predict fabric performance.

The first coherent set of instruments far this type of fabric objective measurement was developed by Kawabata in Japan. While these instruments are accurate, comprehensive and effective, they are also relatively complex, difficult to use and too expensive for all but the largest textile companies. The most recently developed set of instruments (SiroFAST - Fabric Assurance by Simple Tasting) was designed to meet the industrial need for a simple, robust system to predict fabric performance.- Applications:Now let us discuss on of the recent applications of fabric objective management technology, which is the Haptic Simulation of Fabric Hand.Haptic Simulation of Fabric HandIntroductionComputer simulation of virtual environments has improved tremendously in the past several years. It is now possible to simulate not only rigid objects but also flexible materials such as fabric and paper. A logical extension of visual simulation is the capability to feel objects. Haptic research is now yielding results that we all will 'experience' in the near future.Tactile ResponseHuman mechanoreceptor cells respond to a change in external stimulus such as pressure, temperature, etc. The change in the external stimulus is converted to a voltage pulse across neurons. While the voltage pulses occur immediately after the external stimulus, the pulse rate declines over time and returns to normal level. The rate at which the pulse returns to normal after an external stimulus is called the rate of adaptation. Thus there is a change in signal required even if the quantity is static such as roughness of a surface.Based on the sensitivity of the Pacinian and Meissner corpuscles and Ruffini endings, several researchers (Peine et al. Johnson and Phillips) have determined that humans can reliably distinguish, by the tip of their fingers, two points as close as 0.9 mm and that the rate of change of the surface undulations (bandwidth) is around 30 Hz.Tactile Display DevicesTo give the sensation of contact to the skin, some type of device is required to translate the force profiles to a system of actuators. These types of devices have come to be known as 'tactile display'. While 'tactile display' is used to describe all types of HAPTIC feedback systems, Howe makes a distinction between vector force feedbacks and distributed surface contact devices. The skin responds to several distributed physical quantities including high-frequency vibrations, small-scale shape or pressure distribution and thermal properties.Fabric Haptic DeviceCurrent touch feedback systems do not have the sensitivity required for accurate simulation of fabric hand. We developed a new device to meet these requirements. Before we developed a haptic device that can simulate the feel of touch, we used a device called the PHANToM that uses a pen like probe to scan a virtual surface and generate the feel of surface. The two primary parameters required to generate a virtual surface are the frequency of the surface profile and the friction (the drag) of the profile. These two data sets are available from KES measurements of our fabric samples.

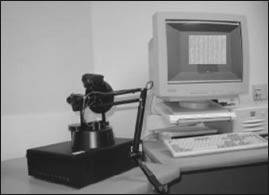

- The PHANToM is a multi-axis feed back system. By holding a pen with a stylus at the end of the PHANToM articulated robot, and moving the pen over a constructed surface in the virtual space, a feed back response can be felt on the hand. The limitation of the device is that the contact with the virtual surface is over a line. However, Katz in his study of surface texture perception noted that it was possible to gain considerable information about a surface by moving a pencil-point across the surface. In the case of fabrics, the contact is over a surface. The PHANToM device, as it exists today, is designed for force feed back applications and does not provide a tactile feeling; we understand this limitation and accordingly designed our own haptic device.Apart from PHANToM, the PhilaU Haptic Device is designed as a combination force feed back and a tactile display. The device consists of a feeler pad at the end of an articulated arm. The feeler pad consists of an array of pins (tactors) with a horizontal spacing of 0.6 mm and a vertical spacing of 0.3 mm. This resolution is adequate to simulate most fabric textures. The bandwidth is 10 Hz which again satisfies the requirement for the simulation of most apparel fabrics. The articulated arm joints are equipped with magnetic brakes that apply a force feed back to the hand holding the feeler pad assembly. The magnetic brakes get their input voltage proportional to surface friction of the fabric, while the tactor pins follow the contour. Together, the device provides a virtual fabric touch and feel.The PhilaU Haptic Device is being improved to include the feeling of compress ional compliance of a fabric. Also, an opposing thumb configuration is being designed for the feeler pad so that a fabric can be felt between the index and thumb of a person. Subjective evaluation of the PhilaU Haptic Device is in progress and initial results are encouraging.Feel the 'Fabric': An Audio-Haptic InterfaceAn objective fabric modeling system should convey not only the visual but also the haptic and audio sensory feedbacks to remote/internet users via an audio-haptic interface. A fabric surface property modeling system consisting of a stylus based fabric characteristic sound modeling, and an audio-haptic interface.

The Stylus Based Fabric Sound Experiment SetupBy using a stylus, people can perceive fabrics surface roughness, friction, and softness though not as precisely as with their bare fingers. The audio-haptic interface is intended to simulate the case of "feeling a virtually fixed fabric via a rigid stylus" by using the PHANToM haptic interface. A DFFT based correlation-restoration method is developed to model the surface roughness and friction coefficient of a fabric, and a physically based method to model the sound of a fabric when rubbed by a stylus. The audio-haptic interface, which renders synchronized auditory and haptic stimuli when the virtual stylus rubs on the surface of a virtual fabric, is developed in VC++6.0 by using OpenGL and the PHANToM GHOST SDK.ConclusionThe KES-F system and SiroFAST are a set of instruments and test methods for the measurement of those properties that relate to the performance The greatest value of the system may prove to be in encouraging communication between fabric and garment manufacturers by allowing the exchange of objective information on performance of fabrics and removing some of the subjectivity from discussions and disagreements of fabrics in garment manufacture and appearance of garments after manufacture and in wear. The various applications like PHANToM and the PhilaU Haptic Device are the efficient tools for fabric objective measurement in today's world.

The Stylus Based Fabric Sound Experiment SetupBy using a stylus, people can perceive fabrics surface roughness, friction, and softness though not as precisely as with their bare fingers. The audio-haptic interface is intended to simulate the case of "feeling a virtually fixed fabric via a rigid stylus" by using the PHANToM haptic interface. A DFFT based correlation-restoration method is developed to model the surface roughness and friction coefficient of a fabric, and a physically based method to model the sound of a fabric when rubbed by a stylus. The audio-haptic interface, which renders synchronized auditory and haptic stimuli when the virtual stylus rubs on the surface of a virtual fabric, is developed in VC++6.0 by using OpenGL and the PHANToM GHOST SDK.ConclusionThe KES-F system and SiroFAST are a set of instruments and test methods for the measurement of those properties that relate to the performance The greatest value of the system may prove to be in encouraging communication between fabric and garment manufacturers by allowing the exchange of objective information on performance of fabrics and removing some of the subjectivity from discussions and disagreements of fabrics in garment manufacture and appearance of garments after manufacture and in wear. The various applications like PHANToM and the PhilaU Haptic Device are the efficient tools for fabric objective measurement in today's world. - References

- T.J. Mahar and R. Pestle. Evaluation of Apparel Fabrics (R.Postle, S.Kawabata and M.Niwa) Textile Machinery Sue. Japan (Osaka), 1983, 262

- R. Postle. Objective Evaluation of Apparel Fabrics (R.Postle, S.Kawabata and M.Niwa) Textile Machinery Sue. Japan (Osaka), 1983, 1

- V.A. Williams. Textile Research Journal, 1985, 55, 312

- T.1. Mahar, I. Ajiki. R. Pestle, and R.C. Dhingra. Objective Evaluation of Apparel Fabrics (R.Postle, S.Kawabata and M.Niwa) Textile Machinery Sue. Japan (Osaka), 1983, 359

- Peine, W.J., Foucher, K.C., and Howe, R.D. Finger speed during single digital palpation, Human Factors, 1997

- Johnson, K.O., and Phillips, J.R. Tactile spatial resolution I., Two-point discrimination, gap detection, grating resolution, and letter recognition, J. of Neurophysiology, 46.6, 1177-1191.

- Kawabata, S., The development of the objective measurement of fabric handles.

- Matsuo, T. Nasu, N and Saito, M., J. Text. Mach. Soc. Japan, 1971, 17, 92.

- Stevens,S.S., Psychology review, 64, 153, 1957.

About the Author:The author is a Lecturer in Department of Textile Technology, K.S.R College of Technology. Tiruchengode.