Flame Resistance of Wool

CSIRO Textile and Fibre Technology, Australia

The fire triangle below shows that three components are required to support conbustion. The presences of fuel, oxygen, and heat are all essential: remove any one of the three and the fire self extinguishes.

Of the normally encountered textile fibres, wool is the most flame resistant. Wool has the most complex fibre structure optimised through evolution to provide thermal protection to mammals. Several factors in this structure are also responsible for wool's natural flame resistance. Specifically, compared with other common fibres, wool:

Of the normally encountered textile fibres, wool is the most flame resistant. Wool has the most complex fibre structure optimised through evolution to provide thermal protection to mammals. Several factors in this structure are also responsible for wool's natural flame resistance. Specifically, compared with other common fibres, wool:

v has high ignition temperature (570 -600 C),

v has high limiting oxygen index (25 -26% ),

v has low heat of combustion and low heat release,

v has high nitrogen content (14%),

v has high moisture content,

v does not melt or drip, and

v forms a self-insulating char that prevents further flame spread.

While most textile fibres are polymers containing mainly carbon and hydrogen that can burn easily, wool also contains high levels of nitrogen and sulphur. In fact many fire retardant additives used for other materials are high in nitrogen. Wool therefore requires higher levels of oxygen in the surrounding atmosphere to accelerate combustion. The limiting concentration of oxygen required to support combustion of wool in standard tests is higher than the ambient oxygen concentration in air (21%). Therefore it is difficult to ignite wool, but once ignited, the flame speads slowly and it is easy to extinguish.

While most textile fibres are polymers containing mainly carbon and hydrogen that can burn easily, wool also contains high levels of nitrogen and sulphur. In fact many fire retardant additives used for other materials are high in nitrogen. Wool therefore requires higher levels of oxygen in the surrounding atmosphere to accelerate combustion. The limiting concentration of oxygen required to support combustion of wool in standard tests is higher than the ambient oxygen concentration in air (21%). Therefore it is difficult to ignite wool, but once ignited, the flame speads slowly and it is easy to extinguish.

Wool fibres are assembled from keratinised cells. The elongated cortical cells in the centre of the fibre are protected from the environment by a layer of cuticle cells. These outer layer cells contain high levels of sulphur. On addition, the fibre is held together by a lightly crosslinked cell membrane complex. When wool is heated to the point of combustion this structure tends to foam providing an insulating layer of pyrolysed material separating heat and oxygen from the fuel.

Due to its natural low flammability characteristics, wool has traditionally been the fibre of choice in many technical applications, ranging from nightwear and protective garments, to transportation andspecialized military requirements.

Fabric structure and density (mass per unit area) together with considered product design are important parameters when considering the flammability performance of textile products. Heavier and denser fabrics with a flat surface together with air excluding designs are known to give the best performance.

The wider fire science community now recognizes that rate of heat release determines the real hazard in actual fire situations and various tests have been developed to measure this property. For example, fibres such as cotton which have a low heat of combustion have a relatively high rate of heat release that determines fire spread rate and burn severity. Wool has both a low heat of combustion and a low rate of heat release.

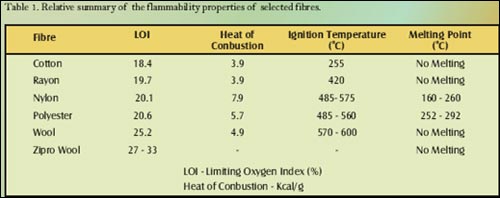

The table below provides a relative summary of the flammability properties of selected fibres, although the actual values vary depending on the test methods employed.

The evolution of increasingly severe mandatory flammability regulations in many aspects of domestic, social and business life has meant that even inherently low flammability fibres, such as wool, require a flame retardant treatment for some applications. Typical applications subject to mandatory flammability requirements include children's nightwear, domestic and commercial furnishings, public transportation and protective clothing.

The flame resistance of all textiles, including wool products, can be improved by selected chemical treatments. Initially, fire retardant treatments for wool were based on the impregnation of borates, phosphates and to a limited degree the organic phosphorus compounds more commonly associated with cellulosic fibres.

The introduction of stricter flammability requirements for airline furnishings resulted from a review of general aviation standards coinciding with the release of wide bodied aircraft in the early 1970's. Many flammability treatments available at the time did not satisfy the new requirements, so The International Wool Secretariat developed a new flame retardant treatment based on the reaction of zirconium or titanium salts with wool. A suite of treatments, based on these two actives, was eventually developed under the generic title of Zirpro, to cover a variety of flammability standards and care claims. The Zirpro treatments can combine flame resistance with shrink resistance, oil and water repellency and in some instances, dyeing.

Zirpro treatments are based on the exhaustion of negatively charged zirconium or titanium salts, under acid conditions, onto positively charged wool. This results in the deposition of only about 3% of flame retardant inside the fibre with negligible effect on properties such as handle. These treatments stabilize and further crosslink the protein structure. The best treatments are colourless; do not alter wool's natural properties, such as handle and moisture adsorption, and tend to be deposited near the surface of the fibre. These treatments tend to increase and strengthen the insulating foam produced as wool is decomposed by heat. Zirpro treated wool also has good durability to washing and drycleaning.

Since the introduction of Zirpro, several different classes of flame retardants have been developed for wool, one of which is based on the application of highly effective halogen donors. The halogens in the treatments tend to interfere with free radical processes that maintain the flame. The use of halogen donors is now restricted by changes to environmental legislation stressing the need to develop alternatives. In spite of the environmental shortcomings, halogens and their derivatives still form a diverse and important role in the flame resist treatment of many products, not just textiles. Alternative treatments are based on phosphorous compounds which tend to lower the thermal decomposition temperature of the textile allowing the volatile fuel to escape before the ignition temperature is reached.

Recent research into flame retardants has focused on the development of intumescent agents. These agents combine the attributes of flame retardancy with the formation of a high thermal resistance insulating char layer. Although originally developed for cellulosics, wool specific intumescents have now been formulated to enhance the natural flame resist and char formation properties of wool.

Wool's natural flame resist properties, the availability of alternative flame resist treatments and the ability to blend wool with flame resist fibres ensures a good future for wool in highly specified, technical and novel end products.