What Is Textile Waste | Definition, Meaning And Types

Introduction

Waste is very common term and we create different types of wastes in our daily life. But have you ever heard about textile or clothing waste? If not then you must go through this article. Or if yes then you should be clarified about the term and its type.

Waste is a kind of thing that you don’t want to produce but produce unwantedly. It has a great economic impact from production process to consumer end. When you use a product for a long time then it becomes a favorite item for you and you don’t want that it becomes wastage. Such as your favorite underwear someday becomes a piece of waste unwantedly. In the same way wastage is a big term for the manufacturers like textile or clothing manufacturers in their production process. When the production quantity is large then the amount of wastage will be high.

Definition of Textile waste

Wastage or waste can be defined as such kind of materials that don’t come into use after the end of the process or the basic use of a product. It is one kind of worthless or useless or defective material.

So textile wastage can be defined as the material that becomes unusable or worthless after the end of the production process of any textile product. Wastage produce in every stage of the textile manufacturing process such as spinning, weaving, knitting, dyeing, finishing and clothing.

Textile wastage is a great threat for any textile industry and the environment as well. When fibre bales are processed through the blow room section in a spinning mill a huge amount of cottonwastage produces. So it is an economic threat. In a dyeing factory tons of fabric dyed and tons of waste water produced which is a great threat for the environment.

Types of Textile waste

Textile wastage can come from different textile manufacturing departments like spinning, weaving, dyeing, finishing, garments manufacturing and even from the consumer end. Now we will know about the details from the below points.

Spinning waste

Cotton fibre bale contains a lot of wastages such as foreign particles, dust, seeds, short fibres etc. and so when processed through different sections of a spinning mill then different types of wastage produced in different sections. The wastage % in blow room is 3% and blow room waste is called lap waste. Carding section wastage % is about 10%. The wastages of carding section are called dropping-1, dropping-2 and sliver waste. The wastage % in draw frame section is about 0.5%. The wastage of this section is called sliver waste. The wastage % in comber section is about 14-15% and the wastages are called noils, lap and vacuum waste. The % of wastage in simplex section is about 0.5% and the wastages are called roving and sliver wastage. The wastage % of ring frame is 2-2.5% and the wastages are called pneumafil, hard waste, vacuum waste etc.

Weaving waste

Like spinning mills different types of wastages found in weaving mills also. Now we will know about it.

Residual yarns which are left on the cones after warping are considered as wastages. In the warping creel section it is not possible to empty all the cones and there will always be a little amount of yarn left on the cones. Sizing waste is another kind of waste in a weaving factory. When in the weavers beam section a new set of warp yarn is started then it is necessary to eliminate some portions of the yarns to ensure that properly sized yarns are wounded on the weavers beam. After sizing wastage, comes the knotting wastage. Knotting is done to ensure all the warp ends of two beams are available for attaching together. Beam residual wastage is another kind of weaving wastage. When a weaver beam is finished, a small amount of warp yarn remains unused on the weavers beam and it is not possible to finish yet. Auxiliary selvage wastage is also a common weaving wastage. Auxiliary selvage is a fake selvage used to hold the weft yarn during loom beat up period.

Knitting waste

Knitting has a glorious history. Knitting can be done on machine or by hand. There are various types of knitting styles and methods. If any fault occurs in the knitting process or any fault in the raw materials there will be knitting wastage. Now we will know about the different types of knitting wastage.

When a new order is created the merchandiser makes sample first. To make sample, trials run in the knitting machine. Due to trials knitting wastage generated. In knitting floor wastage may occur due to yarn. If the cone is faulty or the yarn is faulty then wastage may generate. Fly generation from different yarn guides also cause knitting wastage. There are various types of knitted fabric faults like barriness, spirality, thick and thin place, holes, slubs, sinker marks, stains, stripes etc. Due to these fabric faults knitting wastage generated. Besides due to wrong knitting program, knitting wastage generated.

Dyeing waste

Textile dyeing factories are the most common factories to generate waste water which is a great threat for our environment. Many machine manufacturing companies are trying to introduce new technologies to reduce waste water. Some are trying to develop waterless dyeing methods.

Besides, there are various types of dyeing faults. Due to different types of dyeing faults, wastages generated. The most common dyeing faults are uneven dyeing, batch to batch shade variation, crease marks, selvage to selvage shade variation for denim, metamerism etc. Due to these faults wastage generated in the dyeing floor.

Clothing waste

In a clothing industry there are different types of sections like cutting, bundling & shorting, sewing, printing, embroidery, finishing. In every section wastages produce. Cutting section is the main section to produce wastage in a clothing factory. Due to several roles and marker utilization, a huge amount of wastages produce in the cutting section. After cutting all the body parts are inspected and then shorted and bundled. For this reason some faulty pieces may remain in this section as wastage. Then the loaders take these bundled pieces and distribute in the sewing section. In the sewing section if a worker finds any faulty piece, he rejects it. Due to this reason wastage generated in the sewing section. In the printing section if any print doesn’t match with the standard, the garment piece will be a waste. In the embroidery section, if the embroidery is not done on the proper place, the garment will be treated as wastage. In the finishing section if there is measurement defect, trims or press defect there will generate wastage.

Consumer waste

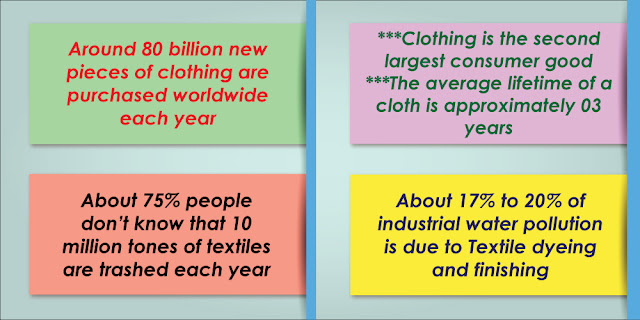

Global clothing production has been doubled from the last decade. The average lifetime of a garment product is approximately 3 years. The average person buys 50% more items of clothing every year and keeps them for about half as long as 15 years ago which generating a huge amount of textile waste.

Conclusion

From the above discussion it is clear that textile waste is generated at the manufacturers end and also at the consumers end. It has no advantage but disadvantage both economically and environmentally. The manufacturers can put emphasizes on new technologies to reduce wastages and the consumers should be more conscious about it. Textile recycling is also a way to minimize wastage.