Antimicrobial finish on textiles using plant extracts

Various natural anti-microbial agents for application on textiles have been explored in this article.

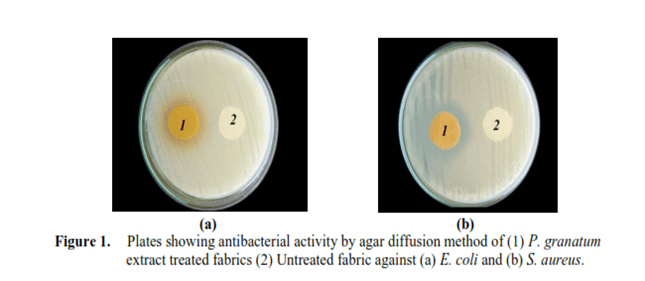

The plant extract treated fabrics were subjected to the antimicrobial activity test against the E-coli and S.aureus bacteria and also the finished samples have been analyzed for their durability of the finish by standard methods. There were no bacteria found on the surface of the treated fabrics and shows an appreciable zone of inhibition against both gram-positive and gram-negative bacteria. The combinatorial plant extracts show a very good zone of inhibition when compared to individually treated fabrics. The treated fabrics also have greater durability. The finish which is applied to the fabric did not affect any physical properties of the fabric. Since these plants are extensively available in the market, the opportunity for implementing this antimicrobial finish in the textile industry is high.

Fabrics generally carry various microorganisms which cause several problems to the wearer. The speedy growth in the textile industry has created many opportunities for a variety of innovative finishes including anti-microbial. In today’s world, naturally, renewable resources are increasingly being required as a result of human dedication to protecting the environment.

Apart from new innovations created using the fabric, value-added finishing gives add up value to the fabric in this situation. During the finishing process, the fabric attains beneficial characteristics like resistance to fire, wrinkle, mildew, etc. These high value-added fabrics have generated a demanding consumer market. In the last few years, there is a growing awareness about the healthy and hygienic surrounding condition.

The diseases normally spread from person to person and through the surface touch of the hands, clothes, etc. of that infected person. Antimicrobial fabrics have its large acceptance as surgical clothes, undergarments, baby clothing, etc. The antimicrobial finishing treatment is now extended to the traditional clothing and the home textiles. The antimicrobial agents kill or inhibit the growth of pathogens to control their effect.

The natural fibres like cotton get easily attacked by the microbes, because of the presence of carbohydrates in the fibre. Antimicrobial finished fabrics have a wide variety of applications in sports clothing, Footwear, medical textiles, furniture, automotive textiles, intimate apparels, etc.

The presence of a microorganism in the fabric causes an unpleasant odour, staining and also causes health problems. Microbial infections cause some danger to the skin and therefore, the garment which is worn next to the skin requires an antimicrobial finish. To protect the skin of the wearer, the application of antimicrobial finish using some herbs are done.

Antimicrobial agents are of two types: leaching and non-leaching. The synthetic antimicrobial agents such as quaternary ammonium compound, triclosan and many others are used for the antimicrobial finish. However, these synthetic antimicrobial agents are durable but they cause many side effects. Currently, the synthetic antimicrobial agents are banned according to the US and European standards, there is an increasing demand for eco-friendly antimicrobial textiles depend on natural antimicrobial agent such as chitosan which does not cause any harm to the wearer.

There are a various variety of herbs which are widely used as a traditional medicine in America, Africa, Europe, etc. for treating various type of diseases. The different parts from the organic plant such as papaya, aloe vera, neem, banana, hemp extracts can also be used for the purpose of antimicrobial finish. Many plants in the world contain the compound which is responsible for the antimicrobial activity. There are various compounds in the plant which is responsible for the antibacterial activity such as tannin, flavonoids, terpenoids, etc. They are both bacteriocides (which kills the micro-organism) and bacteriostatic (which inhibit the growth of micro-organism).

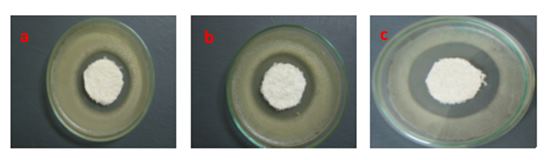

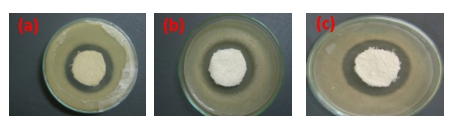

(a) 10% Aloe Gel (b) 10 % Neem and (c) 5% Aloe Gel and 5% Neem

Environment-friendly antimicrobial textile can be produced by the use of plant extracts. Various plants have been gathered and they are tested for their antimicrobial activity. An effective study was regulated to evaluate the plant extracts both qualitatively (AATCC-147) and quantitatively (AATCC-100) for their antimicrobial activity. Although the plant extracts have shown effective antimicrobial activity, the vital issue is the wash durability. The durability of antimicrobial finishing against washing was assessed using quantitative (ICP-OES) and semi-quantitative (LA-ICP-TOF-MS) methods. The physical properties (weight, thickness, fabric structure, count, EPI and PPI) of the fabric before and after application of finish have also been analysed. There are various natural antimicrobial agents available, but limited studies have been carried out for their antimicrobial activity on the textile materials.

Processing of fabric with different plant extracts:

Papaya (Seed and leaf)

The papaya seed and leaves were collected and washed thoroughly. It was dried for 15 days and ground to powder form using a mixer. 5g of powder was mixed in 100ml of distilled water while for solvent extract 70% methanol was used. The solvent extract was kept in the water bath for 1hr at 400C. The extract was then filtered using filter paper to reduce the volume to 10% and the filtrate was collected. It has not applied to the textile substrate due to the absence of OH groups in ortho position which is responsible for binding the extract to the fabric.

The papaya seed and leaves were collected and washed thoroughly. It was dried for 15 days and ground to powder form using a mixer. 5g of powder was mixed in 100ml of distilled water while for solvent extract 70% methanol was used. The solvent extract was kept in the water bath for 1hr at 400C. The extract was then filtered using filter paper to reduce the volume to 10% and the filtrate was collected. It has not applied to the textile substrate due to the absence of OH groups in ortho position which is responsible for binding the extract to the fabric.Aloe Vera

The Aloe Vera gel was collected and dried in the air-dry machine at a temperature of 50°C for three hours. The dried gel was soaked with methanol for one week and it was filtrated through filter paper. The methanol was then evaporated using rotary evaporator machine and the extracted was obtained. The bleached cotton fabric was dipped in the extract for five minutes and it was padded. The treated fabric was dried at 800C for 3minutes and it was cured at 1100C for 2minutes.Neem

The methanolic extract was carried out using the Neem powder and it was left for 48 hours. Then, the methanol was evaporated using rotary evaporated. The extract was applied to the fabric using dip padding technique.Banana (Leaf and Peel)

100g of banana peel was cut into small pieces and boiled in 1L in a solution of 0.1% NaOH. The solution was filtered using filter paper and the extract was collected. The banana peel extraction was used in the dyeing bath at 800C for 90 minutes under continuous stirring. After dyeing, the fabrics were washed with water and it was air-dried.Mango

The leaves were collected and washed thoroughly with water. It was dried under direct sunlight and it was ground into fine powder using a grinding machine. The extraction was carried out using aqueous extraction method at 980C for 60 minutes. The extract was filtered using filter paper three times to get a clear solution. Dyeing was carried out at 800C for 60 minutes at MLR 1:50 in the water bath. The dyed fabric was dried at 800C for two minutes.Pomegranate

The pomegranate was collected and the rind part alone was separated. The pomegranate rind was dried for 3 days and it was ground to fine powder. The ethanolic extraction was done using the pomegranate powder and it left for 5 hours. The extract was collected and the solvent was evaporated using a rotary vacuum evaporator. The dyeing of fabric with extract was carried out at 10% of the weight of the fabric for 30 minutes at 800C on MLR 1:30. After dyeing, the fabric is washed with cold water and dried.

The pomegranate was collected and the rind part alone was separated. The pomegranate rind was dried for 3 days and it was ground to fine powder. The ethanolic extraction was done using the pomegranate powder and it left for 5 hours. The extract was collected and the solvent was evaporated using a rotary vacuum evaporator. The dyeing of fabric with extract was carried out at 10% of the weight of the fabric for 30 minutes at 800C on MLR 1:30. After dyeing, the fabric is washed with cold water and dried.

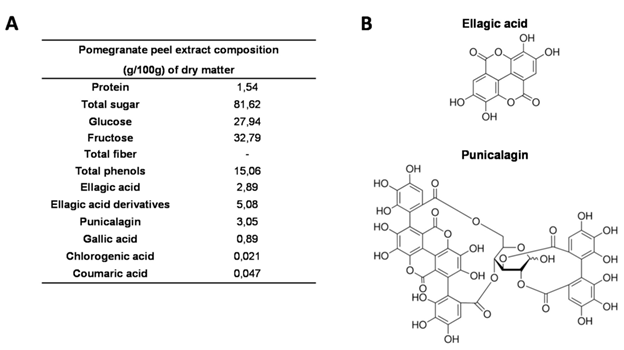

Structure and composition of pomegranate peel (Punica granatum)

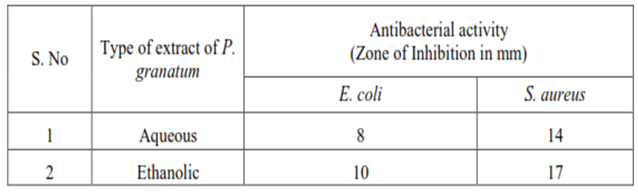

Table 1: Antibacterial activity of pomegranate peel

Combinations

Pomegranate + Onion

The peel of onion and pomegranate was collected. The collected plants were shadow dried and crushed for extraction. The 10 gm powder of selected plants is soaked in 100 ml of distilled water in round bottom flask for overnight. The extraction was done by soxhlet extraction method and the extract was evaporated and concentrated using the rotary evaporator at 500C.Neem + Aloe Vera

Aloe Vera gel was extracted by removing the outer layers of leaves. The gel was smashed for 90 minutes and then filtered. The Neem leaves were collected and dried. It was ground to fine powder by grinding. Then, the methanolic extraction was carried out and the extract was collected. The bleached samples were treated with 5, 7 and 10% concentrations of the aloe gel and Neem extract separately. The same samples were treated with combined aloe gel and Neem extracts of 5, 7 and 10% concentration at 800C for 30 minutes. It was dried at 800C for 15 minutes.Tulsi + Turmeric + Neem

1g powder of each plant was taken and was added to the distilled water. Also, 1% of chloroform is added to each in the distilled bath and allowed to dissolve for 24 hours. The solution was then filtered using a filter paper and filtrate was obtained. The extract was applied to the fabric by the pad-dry-cure method at MLR 1:20.

CONCLUSION

The plant extract treated fabrics were subjected to the antimicrobial activity test against the E-coli and S.aureus bacteria and also the finished samples have been analyzed for their durability of the finish by standard methods. There were no bacteria found on the surface of the treated fabrics and shows an appreciable zone of inhibition against both gram-positive and gram-negative bacteria. The combinatorial plant extracts show a very good zone of inhibition when compared to individually treated fabrics. The treated fabrics also have greater durability. The finish which is applied to the fabric did not affect any physical properties of the fabric. Since these plants are extensively available in the market, the opportunity for implementing this antimicrobial finish in the textile industry is high.

Credits:

Subrata Das, Abarrna Devi R, and Akshaya N

Department of Fashion Technology, Bannari Amman Institute of Technology,

Sathyamangalam, Erode District, Tamil Nadu 638401 India.

Subrata Das, Abarrna Devi R, and Akshaya N

Department of Fashion Technology, Bannari Amman Institute of Technology,

Sathyamangalam, Erode District, Tamil Nadu 638401 India.